Design of transportation and consumer products. Design of parts and assemblies are for performance goals, including safety, and to manufacturing method; machining, casting, molding, or composite layout. Computer Aided Design is used to produce drawing and 3D part files.

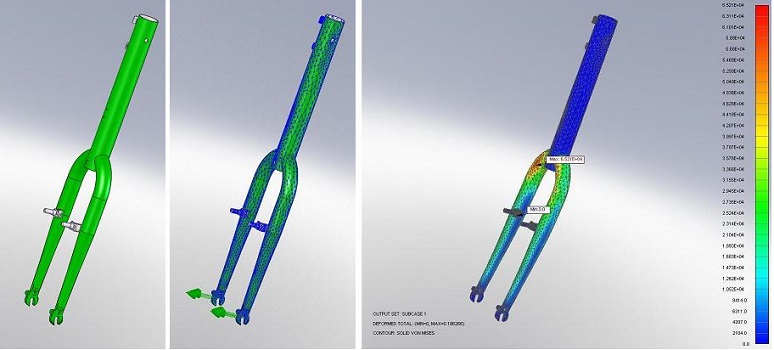

Verification of design is done through analysis and testing. Computer tools like Finite Element and Analysis, FEA, is utilized to check the strength of a part before a prototype is manufactured. Testing is the next level of verification using a loading a prototype, or production articles. 3D Printing of part files is used to make protoypes of design parts, or casts to mold parts.

Reverse engineering or reconstruction is essentially analysis and testing used to determined the conditions that caused an event or failure to occur. This has been done to investigate many bicycle accident cases and bicycle part failures.